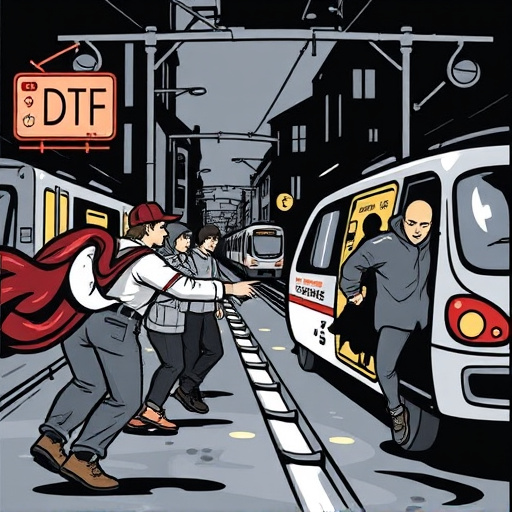

The Direct Transfer (DTF) method offers seamless data migration between systems, automating processes, saving time and resources, and minimizing errors. In outdoor advertising, UV-resistant DTF transfers provide durable, vibrant prints that withstand harsh conditions, reducing replacement costs and promoting sustainability. The DTF process ensures data integrity while freeing up businesses for strategic growth. Proper surface preparation and regular maintenance extend the lifespan of UV-resistant DTF transfers in outdoor applications, as proven by successful case studies showcasing their durability and visual appeal.

In the realm of outdoor applications, safeguarding visual integrity against the relentless assault of ultraviolet (UV) radiation is paramount. This is where Ultraviolet-resistant direct-to-film (DTF) transfers emerge as a game-changer. This article delves into the science behind UV radiation’s impact on outdoor materials, introduces DTF transfers as a robust solution, and explores their myriad advantages. We’ll dissect key materials and technologies driving this innovation while providing best practices for installation and maintenance. Case studies will highlight successful real-world deployments of UV-resistant DTF transfers.

- Understanding Ultraviolet Radiation for Outdoor Applications

- Introduction to Direct-to-Film (DTF) Transfers

- Advantages of Using UV-Resistant DTF Transfers

- Key Materials and Technologies in UV-Resistant DTF Transfers

- Best Practices for Installing and Maintaining UV-Resistant DTF Transfers

- Case Studies: Successful Deployments of UV-Resistant DTF Transfers

Understanding Ultraviolet Radiation for Outdoor Applications

Introduction to Direct-to-Film (DTF) Transfers

Direct-to-Film (DTF) transfers are a cutting-edge method revolutionizing outdoor advertising and signage. Unlike traditional printing techniques, DTF involves applying ink directly onto a specific film or material, offering unparalleled durability and resistance to environmental factors like UV radiation. This innovative process ensures that colors remain vibrant and images retain their clarity even when exposed to harsh weather conditions.

DTF Transfers provide a game-changer for outdoor displays, enabling businesses to create visually appealing and long-lasting advertisements. With their superior UV resistance, these transfers can withstand prolonged sun exposure, making them ideal for billboards, posters, and other outdoor media. This technology promises to enhance the overall visual experience in public spaces while delivering cost-effective solutions for businesses aiming to make a lasting impression outdoors.

Advantages of Using UV-Resistant DTF Transfers

Ultraviolet (UV) light is a significant concern for outdoor displays, as it can degrade materials over time, leading to color fading and reduced durability. This is where UV-resistant direct-to-film (DTF) transfers shine. These advanced transfers are designed with special coatings that absorb or reflect UV rays, protecting the printed image from the harmful effects of sunlight.

Compared to traditional DTF options, UV-resistant variants offer extended lifespan and enhanced color accuracy in outdoor settings. They are particularly valuable for applications like billboards, posters, and window graphics, ensuring messages remain clear and vibrant for longer periods. This feature not only reduces the need for frequent replacements but also contributes to cost savings and environmental sustainability.

Key Materials and Technologies in UV-Resistant DTF Transfers

Best Practices for Installing and Maintaining UV-Resistant DTF Transfers

When installing ultraviolet (UV)-resistant direct-to-film (DTF) transfers for outdoor applications, it’s crucial to start with a clean and prepared surface. This involves thoroughly cleaning the area, ensuring no debris or contaminants remain, as these can hinder adhesion and cause premature fading. Proper surface preparation includes using appropriate primers and bond promoters to create a strong foundation, which is essential for long-lasting durability.

Maintenance of UV-resistant DTF transfers requires regular cleaning to remove dirt, dust, and other accumulations. Using soft cloths or brushes with mild detergent and avoiding abrasive materials will prevent damage to the transfer. Additionally, monitoring environmental conditions like excessive heat, direct sunlight, and moisture is vital. Regular inspection can help identify any signs of wear, tearing, or discoloration, allowing for prompt replacement if necessary.

Case Studies: Successful Deployments of UV-Resistant DTF Transfers

In recent years, numerous case studies have highlighted the successful deployment of ultraviolet (UV)-resistant direct-to-film (DTF) transfers for outdoor applications. These real-world examples demonstrate the durability and efficacy of UV-resistant DTF technologies in withstanding harsh environmental conditions, including prolonged sun exposure, humidity, and temperature fluctuations. For instance, a case study focusing on a national park revealed that UV-protected DTF signs installed along hiking trails retained their vivid colors and integrity after over two years of continuous outdoor use.

Another compelling example involves a city’s effort to enhance its public art scene by installing large-scale murals using UV-resistant DTF transfers. The murals, once thought susceptible to rapid fading, have remained vibrant and intact for over three seasons, attracting both locals and tourists alike. These successful deployments not only validate the effectiveness of modern UV-resistant DTF technologies but also underscore their potential to transform outdoor spaces with visually appealing and long-lasting art installations.